Why do Nuts Come Loose?

Why Do Wheel Nuts Come Loose?

Wheel-off incidents occur when the wheel nuts holding the wheel to the hub lose clamp force. Once clamp force is reduced, vibration and road forces can loosen the nuts until the wheel separates from the vehicle. Several common factors contribute to wheel nuts coming loose:

- Over-torquing – Tightening beyond the manufacturer’s specification stretches studs or threads, reducing their ability to maintain clamp force. This can also cause cracked wheels, seized or cross-threaded nuts, and permanent stud damage.

- Under-torquing – Insufficient torque fails to create the clamping force needed to keep the wheel secure.

- Joint settling – After initial tightening, fasteners may settle as surfaces compress. Failure to re-torque after this break-in period allows nuts to loosen.

- Inadequate vehicle maintenance – Skipping regular inspections and torque checks increases the risk of wheel-off incidents.

- Thermal contraction – When nuts are tightened in a warm shop and then exposed to colder conditions, the studs contract, reducing clamping force.

- Improper mating surfaces – Non-flat surfaces, bent hubs, elongated bolt holes, or damaged wheels prevent proper clamping and allow movement.

- Poor fastener quality – Low-grade bolts and studs are more prone to fatigue and failure.

- Contaminants – Dirt, sand, rust, paint, or metal burrs on threads or mating surfaces create “false torque,” where applied torque is lost to friction instead of clamping force.

- Excessive braking and heat – Heavy braking generates high temperatures that cause studs and nuts to expand and contract. This thermal cycling reduces torque retention.

- Age and wear – Over time, nuts and studs degrade, threads weaken, and the clamp force may no longer be sufficient to secure the wheel.

How to Prevent Wheel Nuts from Coming Loose

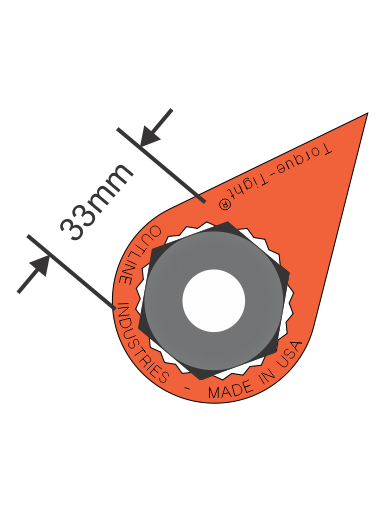

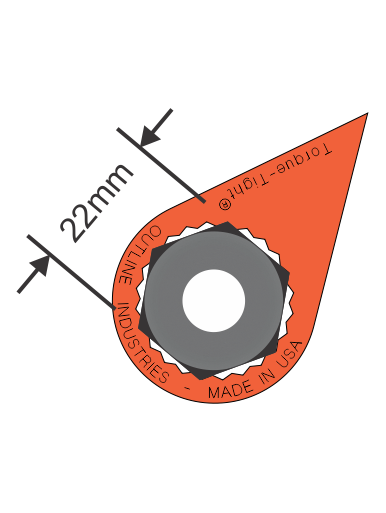

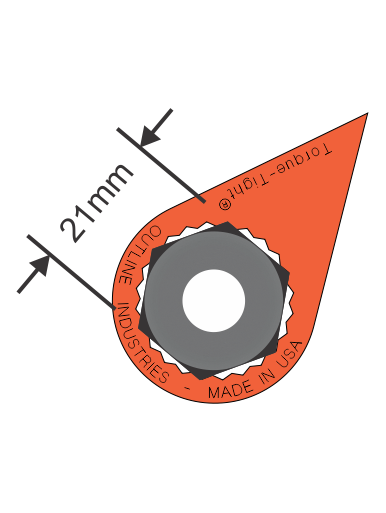

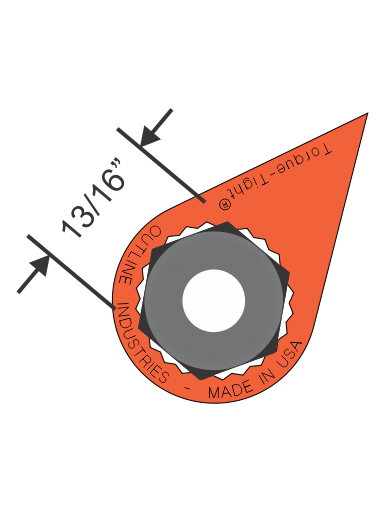

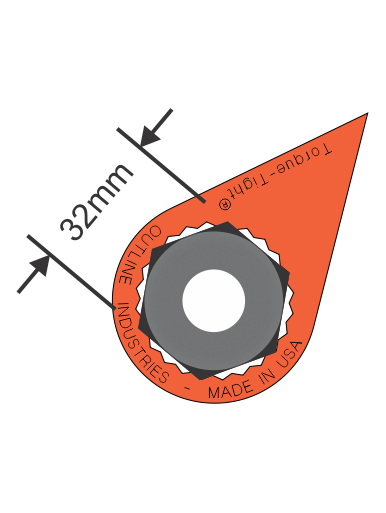

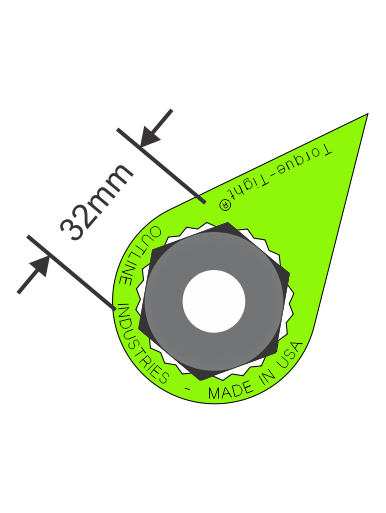

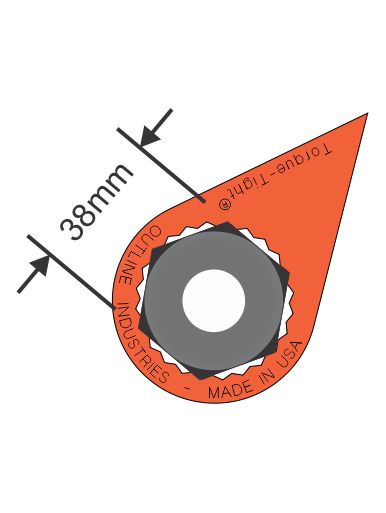

While proper installation, torque checks, and regular maintenance are essential, even the best procedures can’t guarantee wheel nuts will stay secure under all conditions. That’s why fleets and owner-operators rely on Torque-Tight™ lug nut indicators. These simple, affordable devices provide a clear visual warning if a wheel nut begins to loosen — helping drivers spot issues during walkarounds, pass DOT inspections with confidence, and prevent costly wheel-off incidents.

Shop Torque-Tight™ lug nut indicators today and protect your vehicles, drivers, and business from the risks of loose wheel nuts.

Best Sellers

-

Regular price From $12.00 USDRegular price

-

Regular price From $12.00 USDRegular price

-

Regular price From $12.00 USDRegular price

-

Regular price From $12.00 USDRegular price

-

Regular price From $12.00 USDRegular price

-

Regular price From $12.00 USDRegular price

-

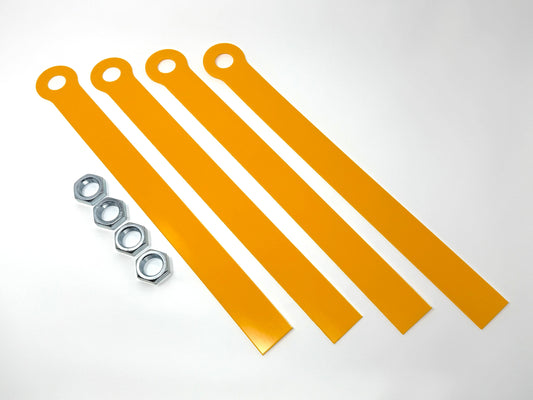

Skid-Stopper Trailer Wheel Skid Indicators with M22x1.5 Jam Nuts

Regular price From $29.00 USDRegular price