Torque-Tight

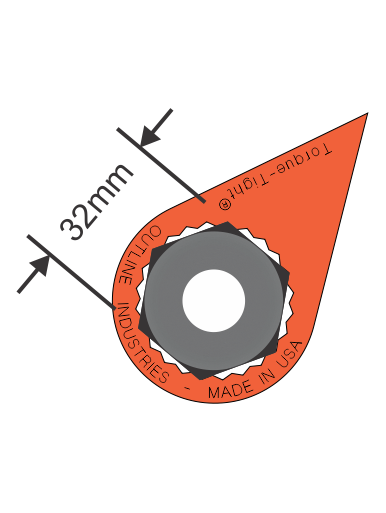

32mm Torque-Tight

SKU:IND32MM-ORN-10

Couldn't load pickup availability

32mm Torque-Tight Loose Lug Nut Indicators

- Fits irregular 32mm lug nuts used on select Class 6, 7, and 8 vehicles

- Installs by hand in seconds

- UV-stable LDPE engineered for harsh outdoor environments

- Heat-stable material designed for high brake and hub temperature cycles

- Instant visual detection during pre-trip and PM inspections

What Are Lug Nut Indicators?

Lug nut indicators, sometimes called wheel nut indicators, are small press-fit devices that attach to each lug nut. Their purpose is simple: show a driver or technician whether a nut has rotated during operation. Any movement is a sign of loosening, which can lead to wheel loss and serious safety risks.

How Torque-Tight Indicators Work

The 24-point design creates a precise interference fit over the lug nut’s hex head. The indicators stay firmly in place through vibration, weather, and heat but can still be installed or removed by hand.

Most fleets point the indicators in a consistent direction. If a nut begins backing off, the indicator rotates outward, making the issue easy to spot during walkarounds.

Why 32mm Is Considered a Special-Use Size

Unlike 33mm, which is standard on most North American Class 8 trucks, 32mm lug nuts are uncommon and typically appear on specific applications such as:

- European brand coach buses

- Skymark airport refuelers and hydrant trucks

- Certain aftermarket or aluminum wheel packages

Because 32mm is not a widely adopted heavy-duty wheel spec, confirming your size before ordering is important. Lug nut indicators must match the exact hex dimension to function correctly.

How To Confirm Your Size

Use a metric socket or calipers. If a 32mm socket fits snugly over the lug nut, these indicators are the correct size. If the nut measures 33mm, use our standard 33mm Torque-Tight indicators instead.

For detailed sizing instructions, see our guide: How to Measure.

Size Guide

- Select European-spec buses

- Skymark airport refueler trucks

- Special-order wheel packages on Class 6–8 vocational trucks

- Any vehicle with a confirmed 32mm hex lug nut

Built for DOT & FMCSA Walkaround Inspections

Torque-Tight indicators provide an instant visual check during pre-trip inspections, supporting fleet compliance with FMCSA 392.7 and standard walkaround procedures.

Pack Size Guide

| Pack Size | Recommended Use |

|---|---|

| 10 piece | Single vehicle or test fit |

| 100 piece | Standard axle sets or small fleet needs |

| 1000 piece | Fleet rollout |

| 4000 piece | Large fleet implementation and stocking |

Specifications

- Indicator size: 32mm

- Material: LDPE (low-density polyethylene)

- Color: UV stable

- Thickness: 1/8 inch

- Design: 24-point pressed-fit pattern

- Temperature resistance: −40°F to over 250°F

- Warranty: 2 years

Share

Collapsible content

Why Fleets Choose Torque-Tight

- Made in the USA with consistent molding quality

- Injection-molded for precise fit and long life

- Color is molded through the part, never painted

- UV-stable polyethylene resists fading and cracking

- 1/8 inch thick for durability and secure fit

- Two-year warranty

How Drivers & Technicians Use Them

- Install all indicators pointing the same direction.

- During pre-trip, look for any indicator rotated outward.

- Any rotation indicates a lug nut requiring immediate service.

Temperature & Environment Performance

Torque-Tight indicators are molded from a high-performance LDPE resin designed for long-term outdoor use. The material remains stable across brake heat cycles, winter cold, UV exposure, and chemical contact.

- Operating environment: −40°F to over 250°F

- Short-duration heat tolerance well above typical brake drum temperatures

- UV-stable colorant prevents fading

- Resistant to oils, grease, salt, and de-icer chemicals

Why We Don’t Use Biodegradable Plastics

Some indicator brands use biodegradable or oxo-degradable plastics. These materials are not recommended for heavy truck environments because they can lose strength when exposed to sunlight, heat, vibration, and road chemicals.

A wheel-end safety device should not degrade outdoors. Torque-Tight indicators use an engineering-grade LDPE chosen for durability, long service life, and consistent performance.

Fleet / Bulk Ordering Information

- Bulk pricing & custom colors available for 5,000+ piece orders

- Packing options for axle sets, small fleets, and full fleet deployment

- W9 available on request

- Purchase orders accepted for approved accounts

Let customers speak for us

from 20 reviewsVery fast delivery helped us get our customer their trailer back sooner than

we predicted.

They went above and beyond to assure my order went out same day for overnight delivery. Super friendly and helpful!!

That's a great idea, who would ever think something so small could be so valuable

Easy to install, simple, and quick. Best way to save thousands of dollars in tires.

Thanks for finding the black torque tight flags. I had bought the whole set for my bus conversion and lost or (?) one, thanks again tom...

We use these on f 550 and they are the only loose wheel indicators that we have found that we can still check torque on the lug nuts without removing the indicators. And they stay on no matter what kind of areas we drive through.

Super fast shipping...item as describe...thanks

Easy application, easiest thing I purchased for my mechanic to do.

Easy to use, fit perfectly, and the best part - everyone on my team loved the idea of using them right away. They made their life easier (less crouching) and safer.

Fast shipping, good price, and made in USA, I'll definitely keep buying from Torque-Tight for my fleet!