Torque-Tight

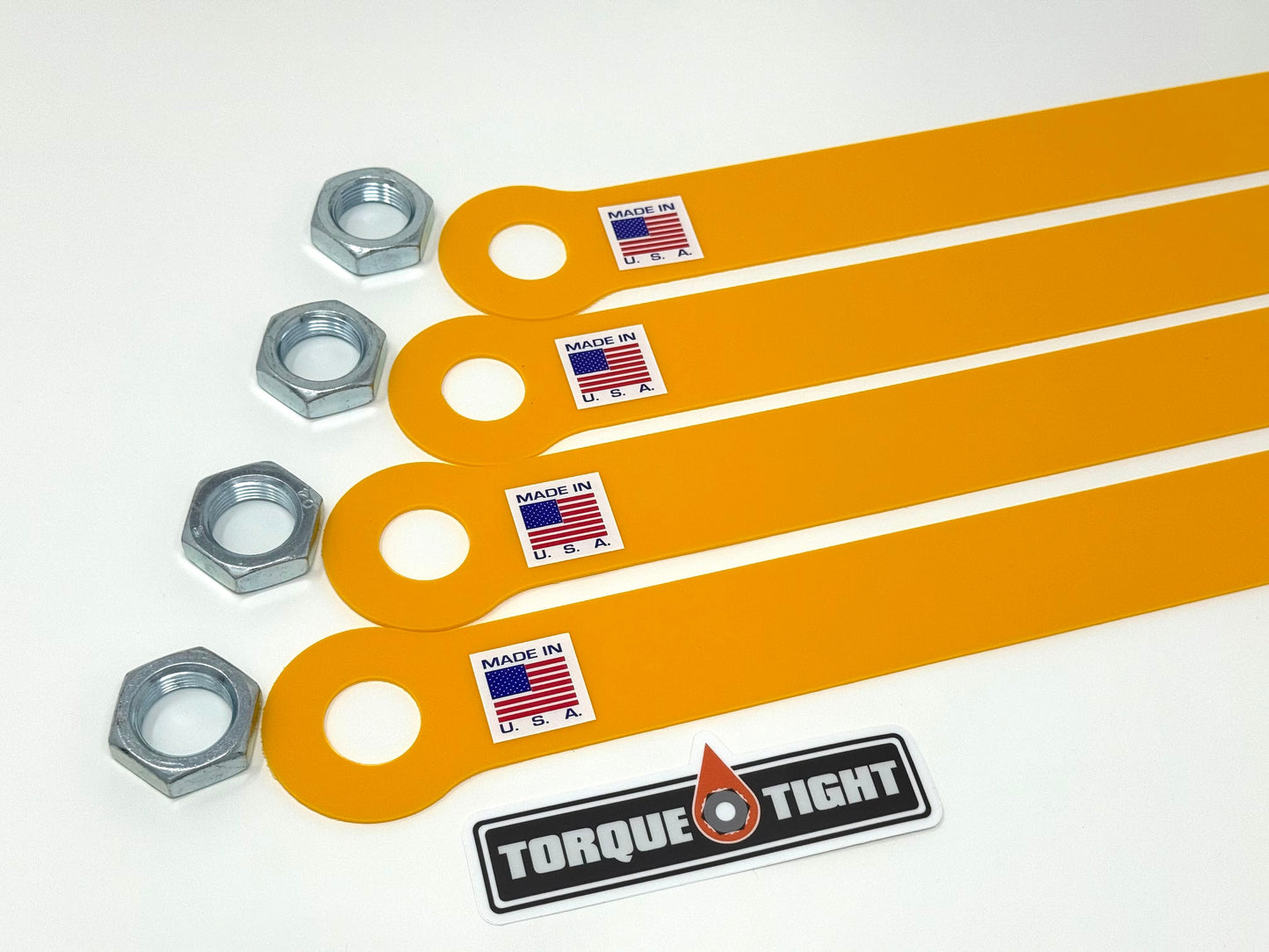

4-Pack Skid-Stopper Trailer Wheel Skid Indicators with M22x1.5 Jam Nuts

SKU:SKID-4PK

Couldn't load pickup availability

Stop Frozen Brakes from Destroying Your Tires

Dragging a locked-up tire due to frozen brakes? We’ve been there too. That’s why we built the Skid-Stopper™ — a simple, ultra-durable way to help you catch frozen or locked brakes before they cost you thousands in ruined tires and downtime.

Built for Extreme Conditions

Skid-Stopper™ indicators are made from UHMW-PE, the same high-performance plastic used in downhill skis. That means they can withstand extreme heat (up to 180°F) and deep cold (down to -200°F) without cracking, warping, or degrading. Skid-Stopper™ is trusted in heavy-duty fleets and is Haul Road Approved.

Why Fleets Use Skid-Stopper™

- Prevents costly tire blowouts caused by dragging frozen brakes

- Improves confidence with a simple visual check

- Enhances fleet aesthetics over spray painted marks on tires

- Made from ultra-durable UHMW-PE material

- Works in extreme hot and cold environments

- Quick installation with included jam nuts

- Reduces downtime and increases driver safety

What’s Included

- 4 × Skid-Stopper™ indicators

- 4 × Jam Nuts (M22x1.5)

How to Install

After installing your lug nut, thread the jam nut on top and sandwich the indicator between the two. Never install between the lug nut and the wheel.

Note on Color

Color may vary slightly from batch to batch due to normal variations in raw material supply. These differences are cosmetic only and do not affect performance or durability.

Share

Collapsible content

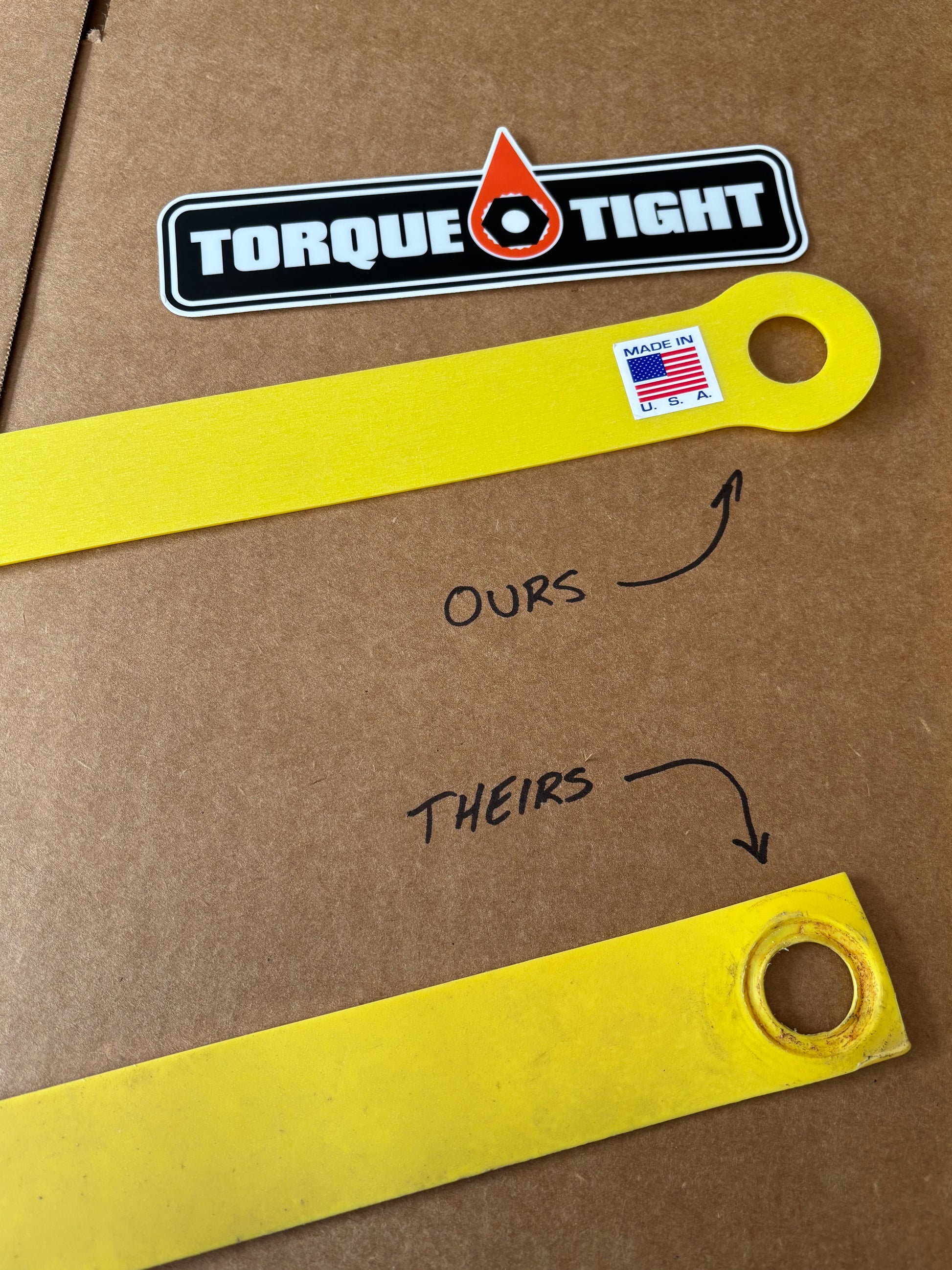

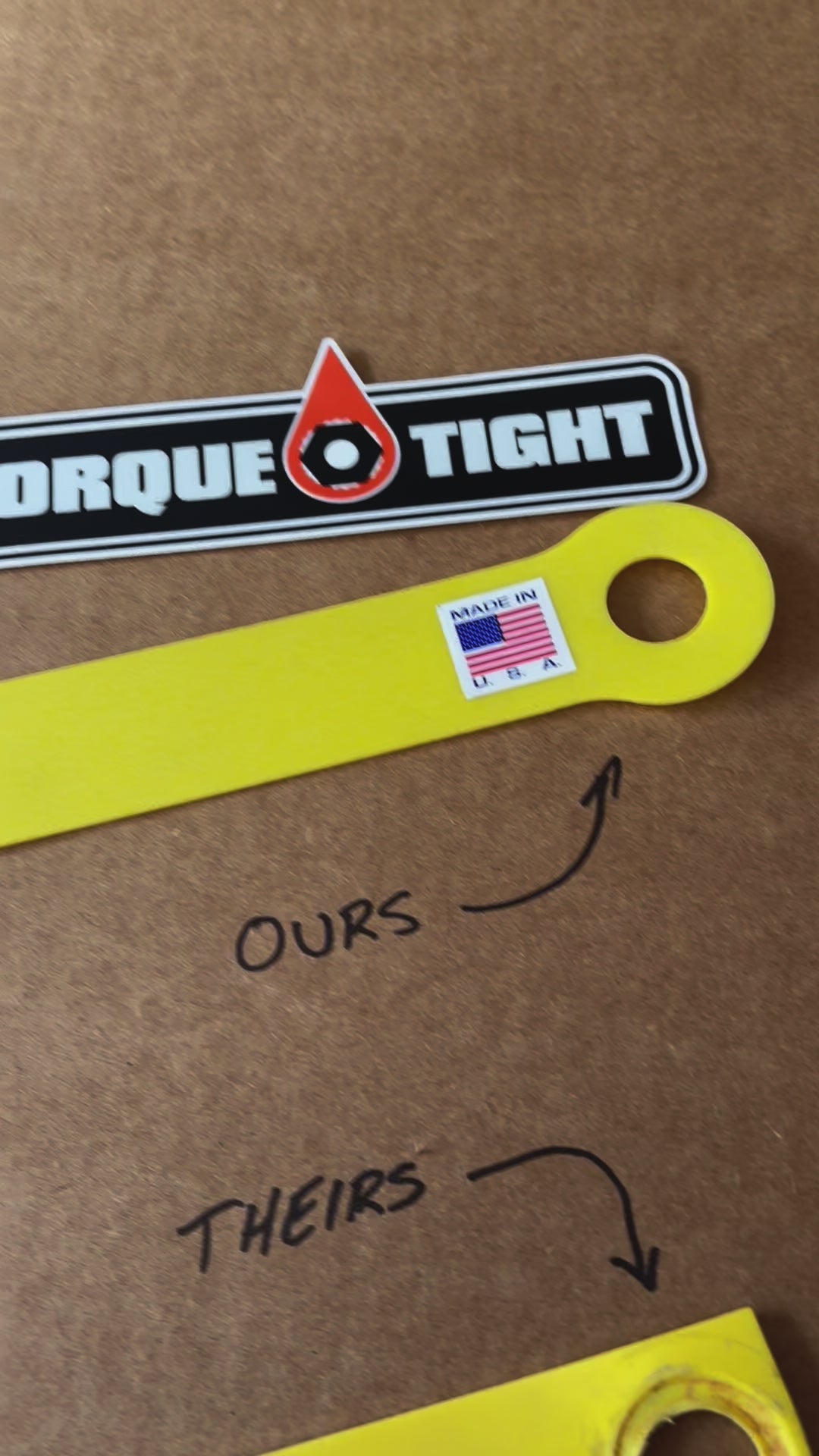

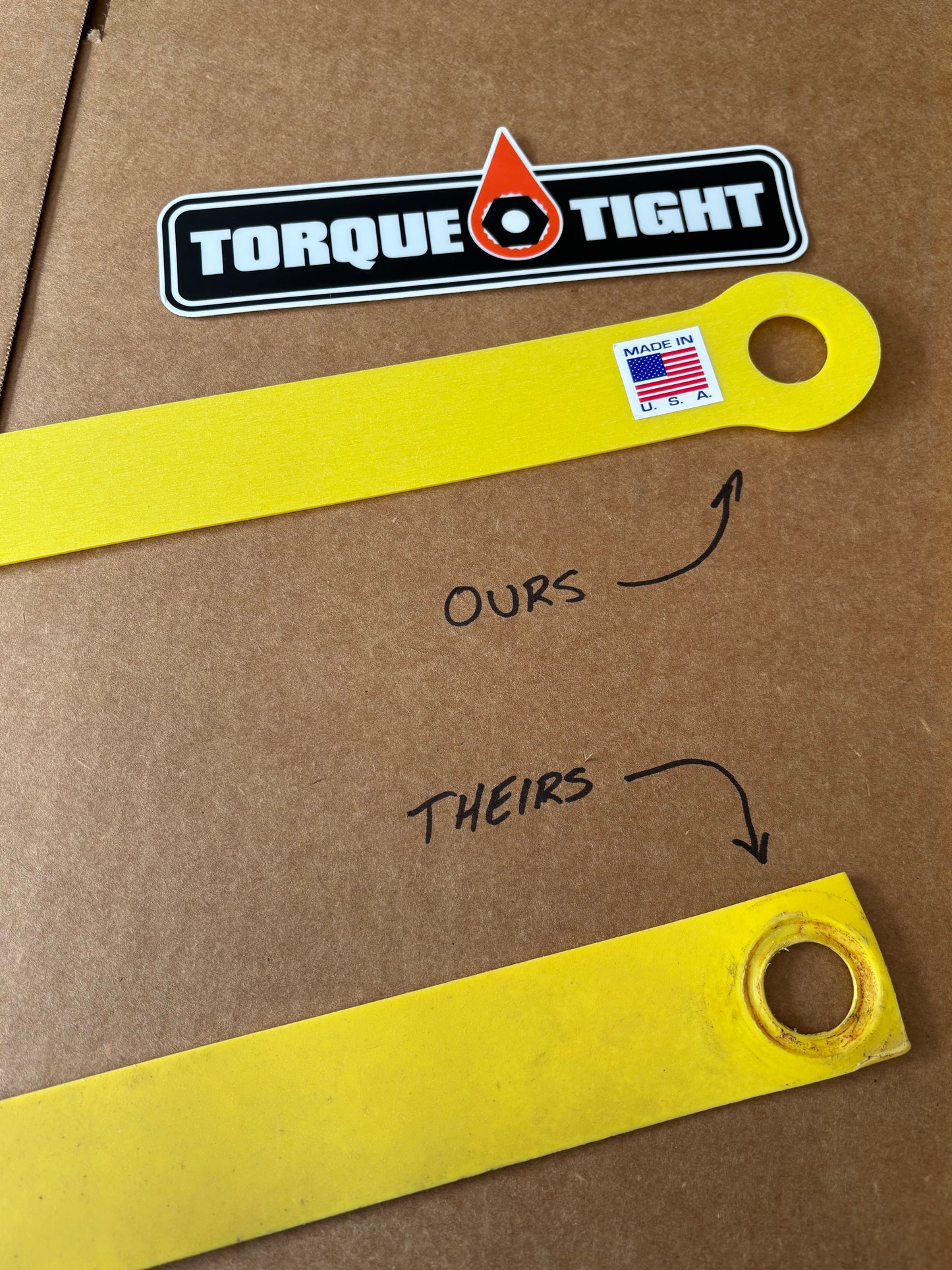

Why UHMW Matters More Than Nylon

Most skid indicators on the market are molded from low cost nylon. It looks fine in a catalog, but nylon becomes brittle in the cold, weakens in UV, and snaps the moment it hits ice or a curb. We got tired of our old ones failing so that's why we created Skid-Stopper™!

Skid-Stopper uses UHMW-PE, the same industrial plastic used in snowplow wear surfaces and downhill skis. UHMW stays stable in deep cold and does not shatter under impact.

- Withstands extreme cold without turning brittle

- Absorbs impacts from ice, curbs, and road debris without cracking

- Resists abrasion so the arm stays visible longer

UHMW isn’t just tougher than nylon, it’s proven every winter in real fleet conditions.

Performance in Extreme Conditions

Skid-Stopper™ indicators are engineered for the environments where frozen brakes actually happen: heavy snow, slush, salt, deep cold, and repeated impacts.

- Rated from -200°F to +180°F without deforming or cracking

- Handles road salt, de-icers, and wash bay chemicals

- Does not warp or curl in hot summers or heavy braking heat

- Keeps its bright, visible shape season after season

This reliability is why Skid-Stopper™ is trusted in heavy-duty fleets and considered “Haul Road Approved.”

Haul Road Approved is not a slogan. It's how we built Skid-Stopper

Haul Road Approved is not a tagline. It is the design requirement we built around. After watching nylon indicators fail again and again, we built our own system using better material and more material in the one place that matters most, the stud contact area.

Could we have taken the shortcut and used cheap nylon or reduced the wall thickness. Sure. But fleets that depend on their rigs cannot afford parts that fail in the first snowstorm or after a curb strike.

Skid-Stopper gives you peace of mind because it is built the way it should have been from the start, with UHMW and the structure to survive real conditions.

Fleet Purchasing and PO Terms

Skid-Stopper is built for fleets, not one-off installs. We support purchase orders, net terms, and consistent replenishment so you can standardize across your entire operation.

- PO support with Net 30 terms for qualified fleets

- Fast turnaround on bulk orders

- Same-day shipping on most stock quantities

- Made in the USA

If you operate a mixed fleet or multiple terminals, standardizing on one reliable skid indicator reduces downtime and simplifies ordering.

Let customers speak for us

from 19 reviewsVery fast delivery helped us get our customer their trailer back sooner than

we predicted.

They went above and beyond to assure my order went out same day for overnight delivery. Super friendly and helpful!!

That's a great idea, who would ever think something so small could be so valuable

Easy to install, simple, and quick. Best way to save thousands of dollars in tires.

Thanks for finding the black torque tight flags. I had bought the whole set for my bus conversion and lost or (?) one, thanks again tom...

We use these on f 550 and they are the only loose wheel indicators that we have found that we can still check torque on the lug nuts without removing the indicators. And they stay on no matter what kind of areas we drive through.

Super fast shipping...item as describe...thanks

Easy application, easiest thing I purchased for my mechanic to do.

Easy to use, fit perfectly, and the best part - everyone on my team loved the idea of using them right away. They made their life easier (less crouching) and safer.

Fast shipping, good price, and made in USA, I'll definitely keep buying from Torque-Tight for my fleet!